What Are Pouch Lithium Cells and How Are They Used in Energy Storage Systems?

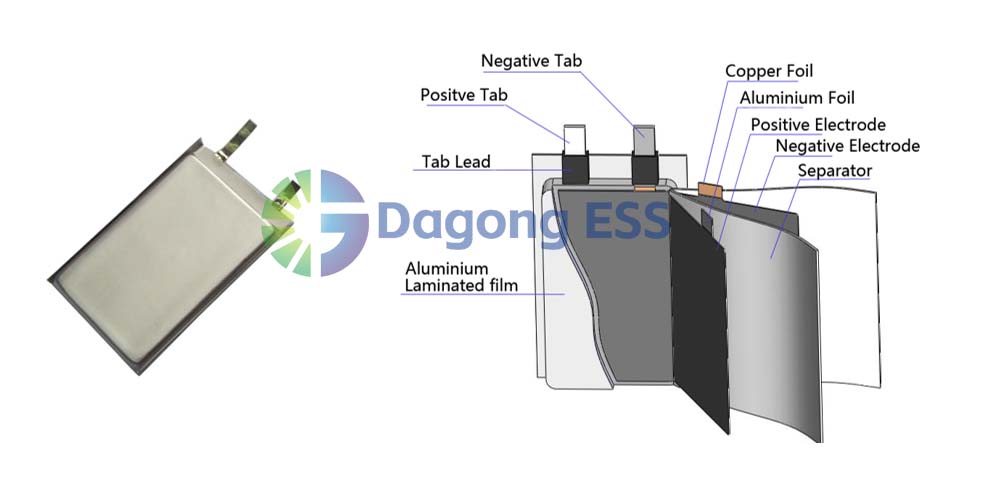

Pouch lithium cells, or pouch lithium batteries, are a type of lithium-ion battery that uses a flexible aluminum-plastic laminated film as the outer casing rather than a rigid metal shell. This packaging method reduces inactive weight, allowing a larger portion of the cell’s volume to be used for active materials. As a result, pouch cells typically achieve higher gravimetric energy density compared with prismatic and cylindrical cells of similar chemistry.

Originally dominant in consumer electronics, pouch lithium cells are now increasingly applied in commercial and industrial energy storage systems (ESS), containerized storage solutions, and emerging high-performance mobility platforms. Their flexibility in shape and size makes them particularly suitable for modular battery designs and systems where space optimization and thermal management are critical.

While pouch cells are not intended to fully replace prismatic or cylindrical formats, they offer complementary advantages that address specific project requirements such as high energy density, flexible module arrangement, and lightweight design.

Pouch Lithium Cell vs Prismatic vs Cylindrical Batteries

Pouch Lithium Cells

Core Advantages: High energy density, flexible sizing, relatively mild pressure release under abnormal conditions, and suitability for next-generation solid-state battery development.

Challenges: Higher production cost due to imported aluminum-plastic film, structural strength relies on module casing, and tighter manufacturing consistency requirements.

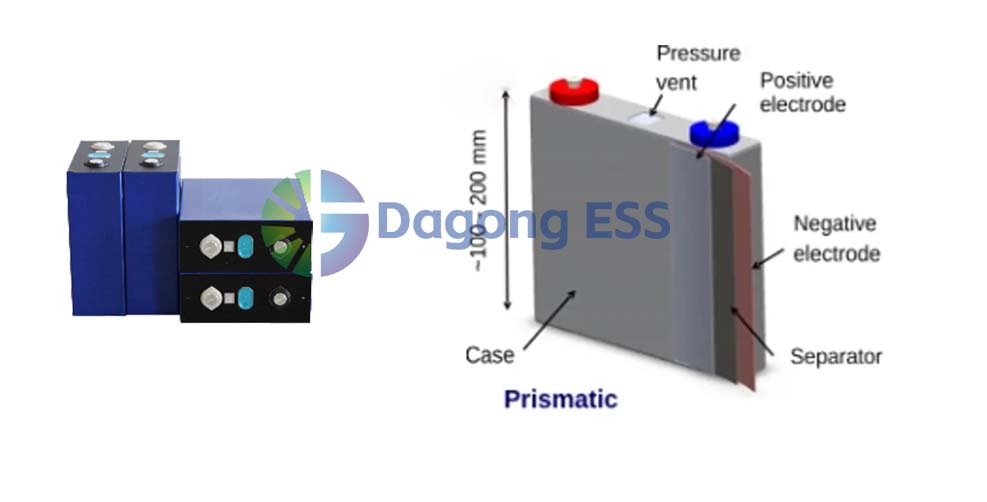

Prismatic Lithium Cells

Market Position: The dominant format in global power batteries, particularly for electric vehicles and large-scale ESS.

Advantages: Rigid aluminum casing provides mechanical protection; mature supply chain and high production efficiency; easy module assembly.

Challenges: Energy density improvement limited by shell rigidity; thermal management becomes complex for large cells; long-term swelling may affect lifespan.

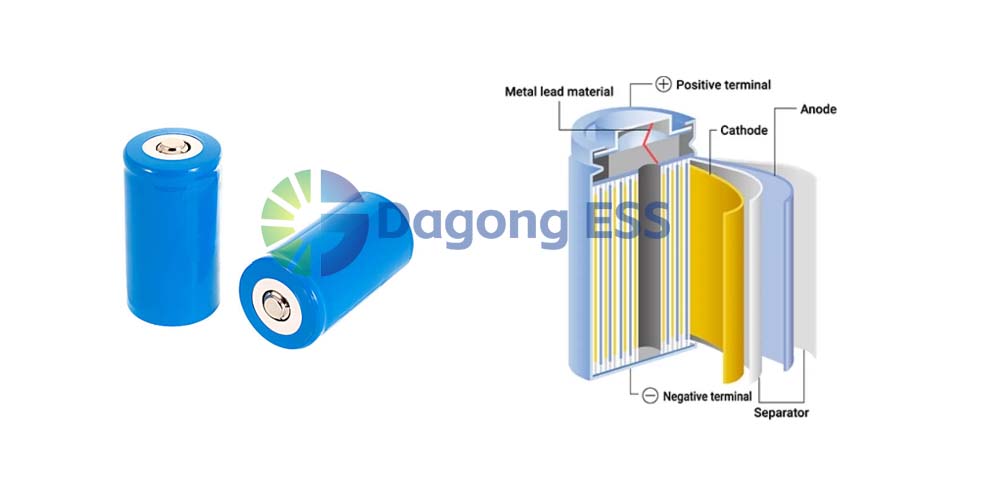

Cylindrical Lithium Cells

Market Position: Differentiated competitor in high-end EVs and industrial applications, often using large formats like 4680.

Advantages: Consistent production, high single-cell safety, excellent high-power performance.

Challenges: System-level energy density may be lower than prismatic solutions; thermal management of large numbers of cells is complex; mass production of large-format cylindrical cells is still evolving.

Key Features of Pouch Lithium Cells: Energy Density, Safety, and Design Flexibility

High Energy Density: Pouch lithium cells minimize inactive materials, maximizing the capacity within a given volume. This is especially valuable in ESS where space constraints exist.

Design Flexibility: Cell thickness, length, and width can be customized, supporting modular stacking and adaptable thermal layouts for commercial and industrial ESS.

Safety Considerations: Pouch cells generally exhibit a more gradual pressure release mechanism, which can reduce the severity of thermal events when combined with appropriate system-level safety measures.

Future Technology Compatibility: Pouch cells are considered suitable for solid-state battery research and potential future deployment, though this technology is still in the development phase.

Applications of Pouch Lithium Cells in Energy Storage and Power Systems

Commercial and Industrial ESS: Pouch-based modules allow efficient space utilization and flexible design for containerized ESS, making them suitable for high-capacity energy storage projects.

High-Density Energy Storage: Pouch cells provide the ability to pack more energy in smaller spaces, supporting applications where weight and volume are critical constraints.

Emerging Mobility Applications: Low-altitude electric aircraft, drones, and other lightweight mobility solutions are beginning to explore pouch cells for their high energy-to-weight ratio, although these are currently pilot-stage deployments.

High-End EVs and Specialized Equipment: Pouch cells can be used to optimize packaging efficiency and performance in applications that require compact, high-density energy storage.

Pouch Lithium Cell Cost and Price Considerations for ESS Projects

The cost of pouch lithium cells depends on factors such as capacity, materials, production scale, and system integration requirements. While they may carry a higher unit cost than prismatic cells due to aluminum-plastic film and manufacturing precision, their system-level advantages—such as modular flexibility, space optimization, and higher energy density—can justify the investment in applications where performance and efficiency are prioritized.

When evaluating ESS projects, overall lifecycle costs, operational efficiency, and safety should be considered in addition to initial cell price.

How to Select Pouch Lithium Cells or Other Battery Formats for Your Project

When to Choose Pouch Cells:

Projects requiring high energy density and lightweight design

Modular and space-optimized ESS

Applications where flexible sizing is critical for thermal management or system layout

When to Choose Prismatic Cells:

Large-scale, standardized ESS or EV battery packs

Cost-sensitive projects where mature supply chains provide advantages

Systems prioritizing proven reliability and integration efficiency

When to Choose Cylindrical Cells:

Applications requiring high power and fast charge/discharge cycles

Systems emphasizing single-cell consistency and quality control

Specialized industrial or high-performance EV use

In many advanced systems, multiple battery formats coexist to fulfill different roles within the same project.

Pouch Lithium Cell Lifespan, Cycle Life, and Reliability

With proper thermal management and system-level protection, pouch lithium cells can achieve over 8,000 charge-discharge cycles and operational lifespans exceeding 15 years in commercial and industrial ESS applications. Environmental conditions, usage patterns, and maintenance practices will directly impact long-term performance.

Why Pouch Lithium Cells Are Gaining Attention in Energy Storage Markets

Pouch lithium cells provide complementary advantages to prismatic and cylindrical formats, particularly in applications where energy density, flexible module design, and space efficiency are critical. They are increasingly relevant in commercial and industrial ESS, containerized storage, and emerging mobility solutions.

While not intended to replace other battery formats, pouch cells represent a strategic option in modern energy storage projects and are expected to coexist with prismatic and cylindrical cells in future systems.

Dagong ESS offers a full range of energy storage solutions compatible with pouch lithium cells, prismatic cells, and cylindrical cells, providing flexible, reliable, and high-performance options for industrial and commercial applications.