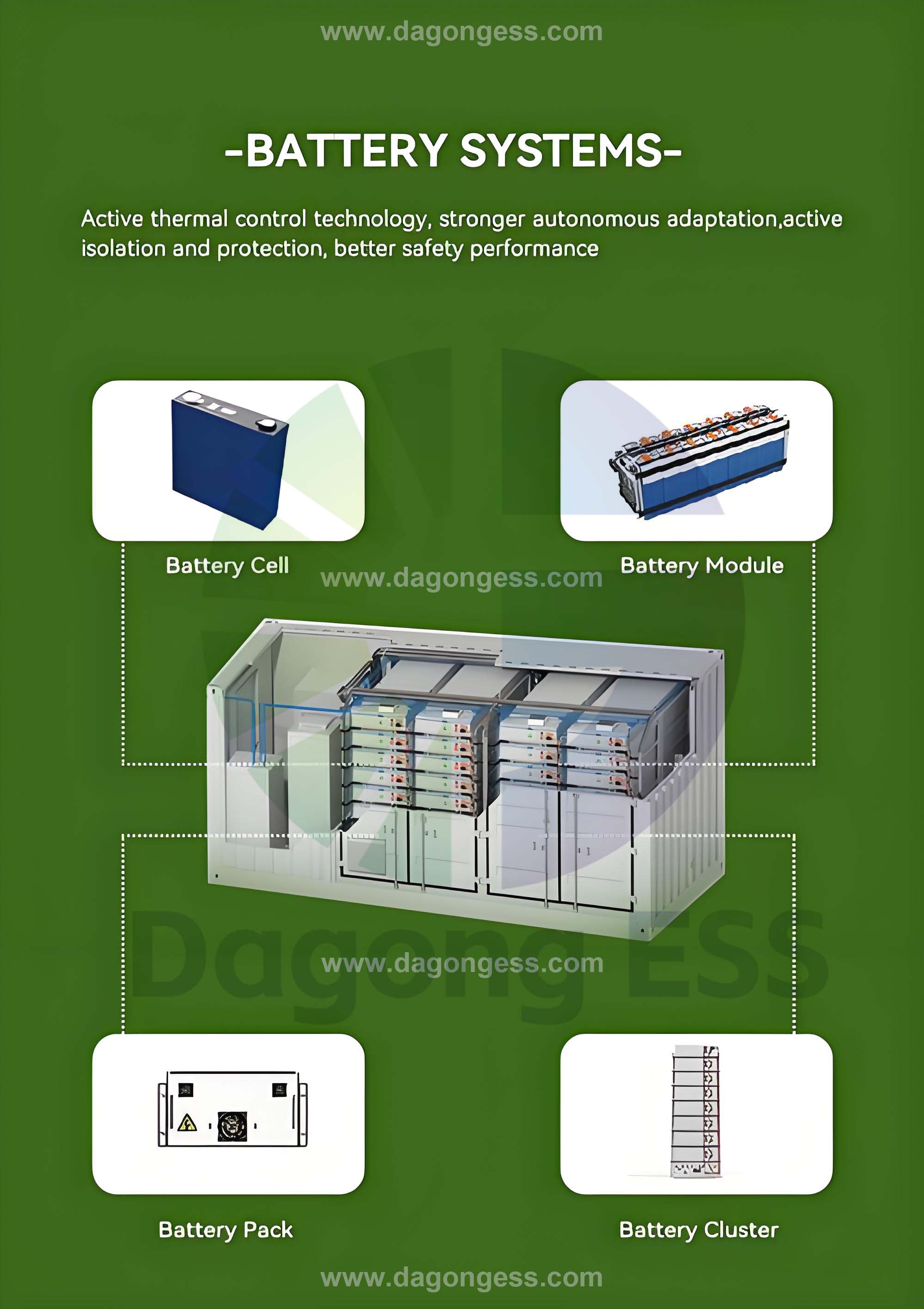

Application of Lithium Battery Packs in Energy Storage Systems

Composition of a Lithium Battery Pack

1.1 Battery Modules

A battery module is formed by connecting multiple cells in series and/or parallel to achieve the desired voltage and capacity. The number of cells varies depending on the system design, with common configurations including 8, 9, 10, 12, 13, or 14 cells. For example, a 1P48S pack typically consists of four 12S modules, while a 1P52S pack can be built from either four or eight 13S modules.

1.2 Electrical Connection System

This includes high/low-voltage harnesses, copper busbars (CCS), quick connectors, communication lines, and protective devices—ensuring stable power delivery and reliable communication.

1.3 Thermal Management System

Thermal regulation is vital for safety and performance. Pack systems may use air cooling (via AC systems) or liquid cooling. Liquid cooling is available in cold-plate and immersion types. The goal is to maintain temperature variations within 5°C and keep the system within the optimal operating range of 25°C ±5°C.

1.4 Enclosure

The enclosure includes a frame, upper and lower covers, metal supports, panels, and fastening screws. It provides structural stability and simplifies installation and transport.

1.5 Battery Management System (BMS)

The BMS monitors key parameters such as voltage, current, and temperature, and balances the cells to ensure uniform performance. It also uploads data in real-time to the EMS (Energy Management System), enabling smart operation of the energy storage system.

Core Technologies of Lithium Battery Packs

2.1 Cell Sorting and Matching

Advanced algorithms and high-precision testing equipment are used to sort and match cells with similar voltage, internal resistance, and capacity to ensure performance consistency and reliability.

2.2 Welding Techniques

Laser and ultrasonic welding are commonly used to connect cells with busbars and soft connectors. These methods enhance the strength, conductivity, and safety of the pack.

Two major connection methods are:

Welded connections (laser, ultrasonic, pulse welding): High reliability but less convenient for replacements.

Elastic metal contacts: Easier maintenance but with potential risks of poor contact.

Battery packs also include components like busbars, protective boards, connectors, insulating materials (such as fish paper), and plastic brackets. All cells within a pack must be of the same type and model, with differences in capacity, voltage, and resistance not exceeding 2%.

Technical Pathways in Pack Design

3.1 Low-Voltage vs. High-Voltage Systems

Low-voltage systems (48V/51.2V, typically 1P16S): Popular in cost-sensitive markets like Africa, South America, and Southeast Asia. These systems use mature technologies, are easier to install and expand, and support large-capacity 280Ah cells. However, they suffer from higher energy loss due to large currents.

High-voltage systems (100V–1500V): Formed by connecting multiple packs (e.g., 1P48S, 1P52S, 1P104S). These systems offer higher efficiency due to lower current and reduced copper loss, and are mainly used in three-phase residential, C&I, and containerized ESS. However, they require more complex insulation, safety measures, and high-end BMS components due to increased voltage.

3.2 Cell Form Factors: Prismatic vs. Pouch vs. Cylindrical vs. Large Cylindrical

Cylindrical cells: Popularized by Tesla’s Powerwall, these integrate small cells like 18650 or 21700 in large quantities.

Prismatic cells (aluminum case): The most widely used in ESS due to their compact size, thermal stability, and ease of thermal design—especially for liquid cooling.

Pouch cells: Lightweight, with high energy density and safety, ideal for portable devices. However, they are more difficult and costly to manufacture.

Large cylindrical cells: Offer good energy density and emerging as a new trend.

3.3 Cell Capacity Options

Cell capacities vary by type:

Prismatic: 50Ah–314Ah

Large cylindrical: 10Ah–50Ah

Pouch: 30Ah–80Ah

50Ah and 100Ah prismatic cells are widely used in high- and low-voltage home storage respectively. Newer trends include using 280Ah cells in low-voltage systems (1P16S configuration yields 14.3kWh), and 1000V/1500V systems for C&I storage using 1P48S, 1P52S, or 1P104S configurations.

Dagong ESS Products Showcase

Dagong ESS offers customized lithium battery pack solutions to meet diverse global energy storage demands, including residential, commercial, and utility-scale applications. Our systems are designed with safety, efficiency, and scalability in mind—empowering a smarter and greener energy future.

14.33kWh Air-Cooled Energy Storage Battery Pack: The 14.33kWh air-cooled battery pack belongs to the energy storage system (ESS) category and is specifically designed to store electricity generated from renewable energy sources such as solar and wind power. It provides power during high demand or outages and features an air-cooling system for optimal temperature management.

46.5kWh Liquid-Cooled Energy Storage Pack: The 46.5kWh liquid-cooled energy storage pack is part of the ESS category and is designed for residential and commercial energy storage applications. It is specifically intended to store and supply energy during peak demand or power outages, featuring a liquid-cooling system to ensure optimal temperature management.

Customized Energy Storage Battery Packs

At Dagong ESS, We offer a variety of customized solutions to meet the diverse needs of residential and commercial applications. Customization options include battery cells, protection levels, Battery Management System (BMS), and capacity. Details are as follows:

Battery Type: Choose battery chemistry based on factors such as cycle life, cost, and safety.

Capacity: Customize the capacity of the battery pack according to specific requirements.

Voltage: Select different nominal voltages based on system requirements and compatibility.

Cooling Method: Choose between air-cooled or liquid-cooled designs based on environmental conditions and cooling efficiency needs.

Protection Level: Customizable protection features, such as IP ratings (e.g., IP20, IP67), to ensure safe operation in both indoor and outdoor environments.

Battery Management System (BMS): Customize the Battery Management System (BMS) with features such as remote monitoring, advanced safety protocols, and real-time performance tracking.

Frequently Asked Questions

Q1:What are lithium battery packs used for?

A:Lithium-ion (Li-ion) batteries are used in many products such as electronics, toys, wireless headphones, handheld power tools, small and large appliances, electric vehicles and electrical energy storage systems.

Q2: Are lithium battery packs safe?

Q3: Can existing packs be expanded/upgraded?

A: Yes! Our modular design allows adding/replacing packs easily.